RESEARCH

Water reuse has become an important and indispensable component of the urban water system in many cities around the world. The practice supplements freshwater supplies and increases water security. Notable examples have been reported in Windhoek, Namibia and Orange County in Southern California, which practice direct and/or indirect potable water reuse (DPWR/IPWR) from sewage in a safe manner. Other notable water reuse examples can be found in Singapore and Australia. The potential shown in these cases has motivated water scientists and engineers to upgrade existing technologies designed for solving problems of polluted surface water (Water 3.0) to ones that can increase production of potable water from wastewater (Water 4.0).

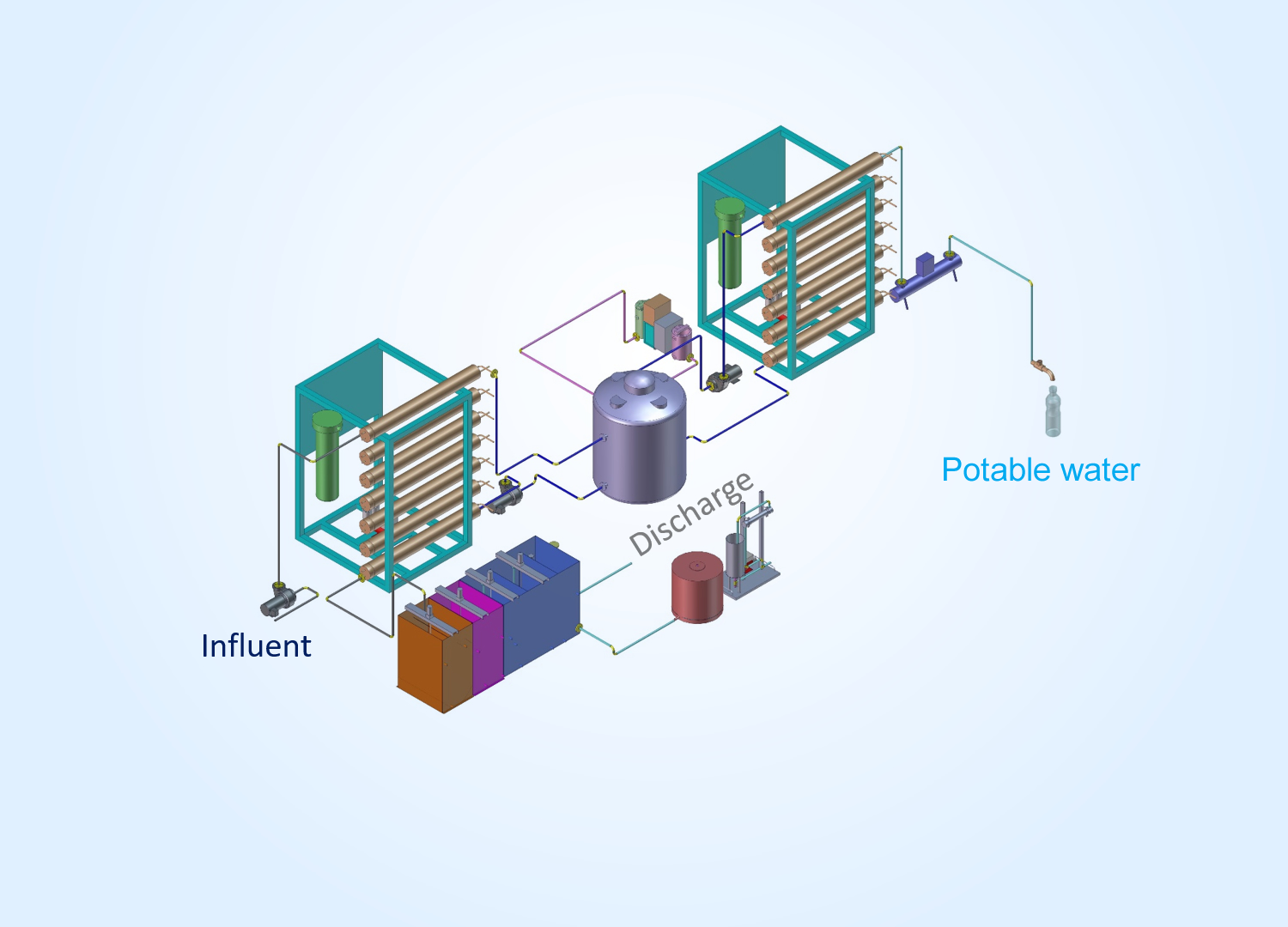

Our approach is to develop a next-generation urban water treatment system

Waste Water to Resource Factory (WWRF) that is highly compact and energy efficient with a high recovery rate of both potable water and other resources.

This new water system consists of four steps each with its own technological breakthroughs.

Step 1

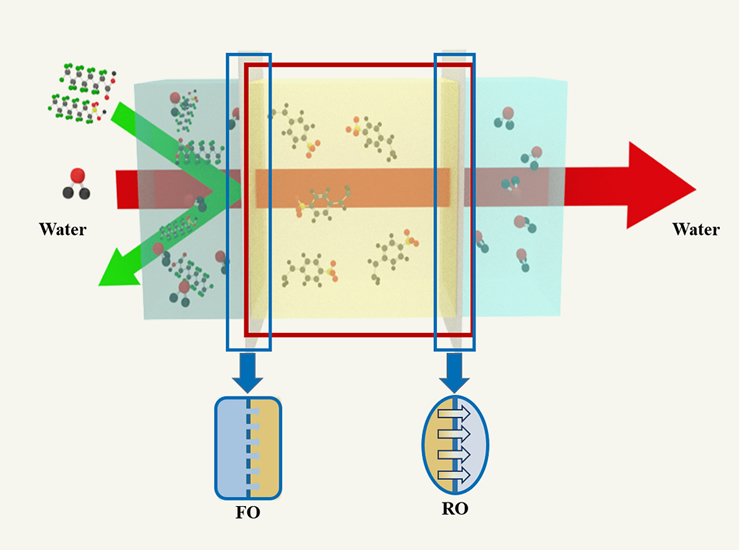

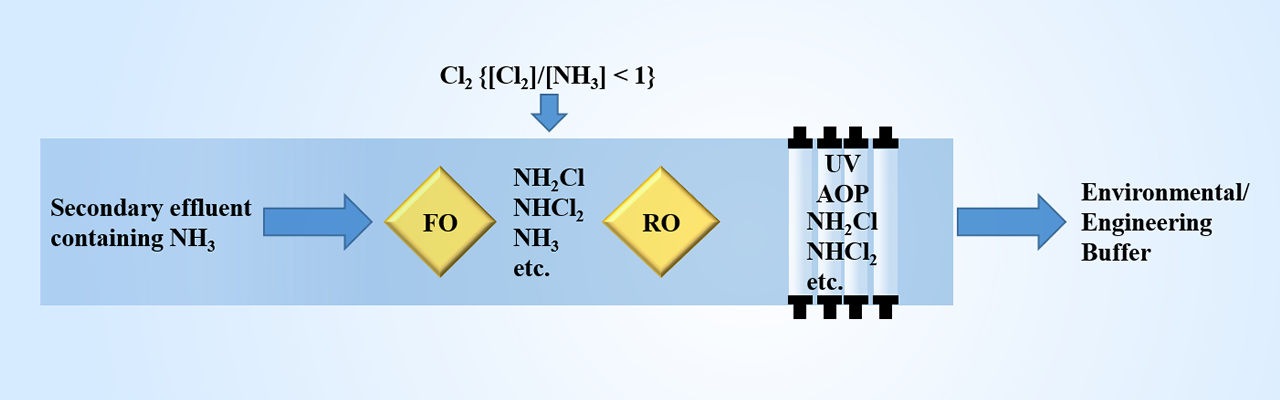

An advanced Hybrid Forward osmosis and Reverse Osmosis (hereafter referred to as HFRO) system will be developed to directly treat the primary wastewater effluent. A large portion of water (50–90%, depending on initial salinity) containing trace levels of pollutants will pass through this hybrid system for potable water production. The forward (FO) membrane will pre-concentrate the major pollutants (e.g. organic-carbon, nitrogen, suspended solid and salt content) to the rest 10-50% of the feed sewage volume.

Task-IA – Leader: Alicia An

Step 2

The HFRO permeate will be further treated by a new Chloramine/UltraViolet AOP process, hereafter referred to as C/UV-AOP, to degrade emerging micropollutants and inactivate pathogens as well as antibiotic-resistant bacteria (ARB) in the permeate, via chloramine produced by in-situ electrolysis of both chloride and an ammonia-rich draw solution of HFRO. The chloramine will further act to control biofouling of the FO and RO and help with post-disinfection in water reuse.

Task-IB – Leader: Chii Shang

Step 3

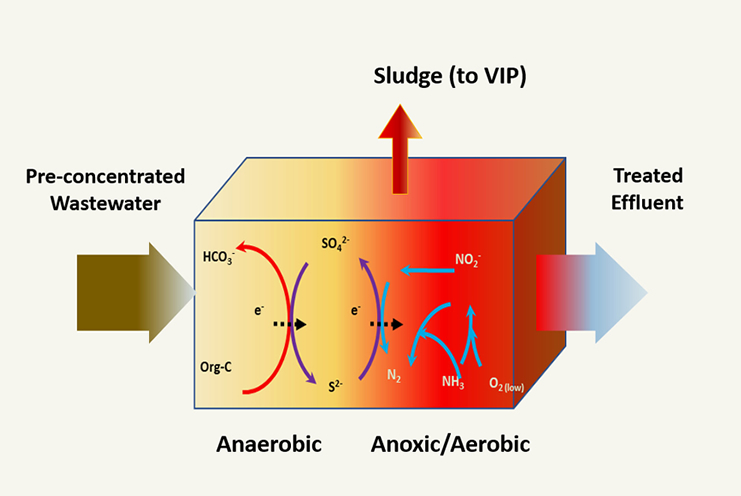

The pre-concentrated sewage will be treated by a new saline microbiology-based biological process called Sulfur-conversion and anamMOX (SMOX) for the removal of residual chemical oxygen demand (COD) and nitrogen. It will produce minimal sludge and require very limited aeration due to efficient anaerobic organics removal by sulfate (from concentrated sewage of the FO). Consequently, it will generate sulfide and high pH (>8; dissolving almost all produced sulfide in water). The dissolved sulfide will then drive partial autotrophic denitrification, thus providing nitrite to sustain the anammox reaction for nitrogen removal. The only oxygenation step will be the conversion of some of the ammonia to nitrite and/or dissolved sulfide to poly-sulfur for recovery as a resource when necessary.

Task-IIA – Leaders: Tong Zhang & Guang-Hao Chen

Step 4

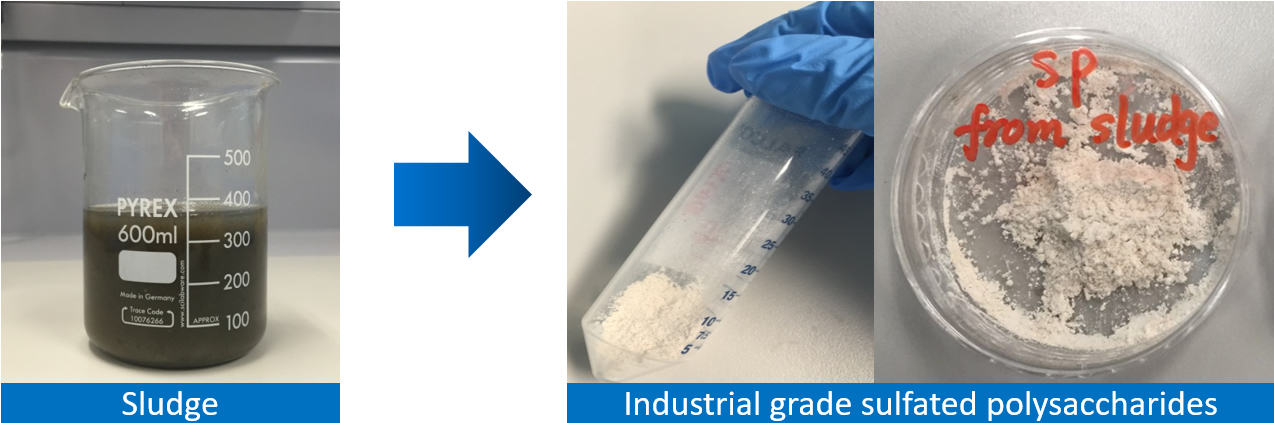

The SMOX process produces a tiny amount of excess biological sludge by nature. Because concentrated saline sewage is rich in carbon and sulfate, bioactive sulfated polysaccharides (SPs) will be generated in SMOX sludge and bound in its extracellular polymeric substances (EPS) matrix. These chemicals are very valuable. We have invented a technology called Valuable chemIcal Production (VIP) to recover these valuable chemicals from SMOX sludge, which can offset the cost of sludge treatment and disposal.

Task-IIB – Leaders: Guohua Chen & Peter Cheung

Pilot-scale Demonstration

The novel processes developed above will be demonstrated in a pilot-scale plant to evaluate its engineering and economic feasibility and its health, environmental and ecological impacts under realistic conditions.

Task-III – Leaders: Wen-Xiong Wang & Guang-Hao Chen